0832200273

Abstract:

Today's business climate has rapidly changed and has become more competitive as ever in nature. Creating value through supply chain integration has become a potentially valuable way of securing competitive advantage and improving organizational performance, since competition is no longer between organizations, but among supply chains. The integration of a supply chain not only focuses on tangible resources and assets, but also on intangibles such as knowledge. Thus, the effective creation of knowledge has become a top priority in a supply chain. Knowledge is becoming the only resource capable of offering competitive advantage and continued growth and prosperity for supply chain partners. This study will be using Wal-Mart case study, how they create a distinct virtual space for knowledge exchange and creation with its suppliers.

Keywords: Knowledge Management, Supply Chain Management, Collaborative Supply Chain, Network Supply Chain, Wal-Mart.

1. Introduction

Today's business climate has rapidly changed and has become more competitive as ever in nature. Businesses now not only need to operate at a lower cost to compete, it must also develop its own core competencies to distinguish itself from competitors and stand out in the market.

In order to create a niche for competitive advantage, companies must look at the big picture of the whole process, and figuring out which process can be reduce, eliminate, raise and create. Creating value through supply chain integration has become a potentially valuable way of securing competitive advantage and improving organizational performance, since competition is no longer between organizations, but among supply chains.

The supply chain is a highly complex area. As a result, it can be a source of great efficiency and cost-savings gains. Companies are realizing that more than ever, supply chain excellence drives competitive advantage, customer relationships and shareholder value.

The strategy on applying SCM will not only impact their market positioning but also strategic decision on choosing the right partners, resources and manpower. By focusing on core competencies also will allow the company to create niches and specialization of core areas.

The integration of a supply chain not only focuses on tangible resources and assets, but also on intangibles such as knowledge. Thus, the effective creation of knowledge has become a top priority in a supply chain. Knowledge is becoming the only resource capable of offering competitive advantage and continued growth and prosperity for supply chain partners.

This study extends the concepts in the supply chain and knowledge management literature on the impact of knowledge management on supply chain performance especially in a complex supply chain network. The study will be using Wal-Mart case study and the discussion will be on Wal-Mart supply chain system, knowledge management system, collaboration with suppliers, knowledge in organization, what kind of knowledge and information does Wal-Mart share with its supplier, and what are the issues and key success in implementing Knowledge Management in their Supply Chain Network.

2. Literature

2.1 Supply Chain Management

According to Turban (2008) a supply chain is defined as a set of relationships among suppliers, manufacturers, distributors, and retailers that facilitate the transformation of raw materials into final products. The supply chain includes all interactions between suppliers, manufacturers, distributors, warehouses, and customers. Supply chains also include the organization processes for developing and delivering products, information, and services to end customers.

There are typically three of flows in the supply chain: materials, information, and financial. In managing the supply chain, it is necessary to coordinate all the flows among all the parties in the chain.

1. Material flows. These are all physical products, raw materials, supplies, and so forth, that flow along the chain. The concept of material flows also includes reverse flows—returned products, recycled products, and disposal of materials or products.

2. Information flows. This includes all data related to demand, shipments, orders, returns, and schedules, and changes in data.

3. Financial flows. The financial flows are all the transfers of money, payments, credit card information and authorization, payment schedules, e-payments, and credit related data.

SCM Goals are to reduce uncertainty and risks along the supply chain, thereby decreasing inventory levels and cycle time, and improving business processes and customer service. All of these benefits contribute to increased profitability and competitiveness.

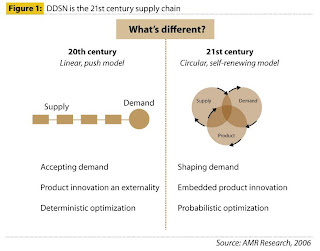

2.1.1 Linear Supply Chain and Network Supply Chain

The rapid development of internet technology has changed the anatomy of supply chain management from a traditional (Linear Supply Chain) into an adaptive and flexible (Network Supply Chain).

In a linear supply chain, the products and information move in a linear flow, from suppliers to the factory, and then to the wholesalers and then finally to the retailers. While in the network supply chain, the products and information can move freely from one entity to another organization. With network supply chain, the organization will always find ways to improve their processes and business activities so it can be better, faster, and cheaper.

A supply chain network is a network interrelated activities of procurement, production, distribution, vendition, and consumption of one or more products, conducted by coalitions of business entities who act collectively within a coalition. In other words, network of interrelated supply chains.

Fig. 1: Traditional Supply Chain vs. Network Value chain

A good example of a successful network supply chain is Wal-Mart. Wal-Mart eliminates the role of wholesaler. They directly buy the products from the manufacturers and put them in the distributions centre before they distribute the products to each retail store. However as Wal-Mart keep innovating, the products can move directly from the manufacturers to the customer, or to the retail stores without the needs to manage it in the distribution centre first.

However, the paradigm to change from linear supply chain to the network supply chain is not easy, because it requires:

- In-depth understanding on the new concept and philosophy

- New management structure of supply chain management

- New leveraging technology

- Collaboration among suppliers, customers, and business partners.

The process transitions are described as below:

- Process enablers—management of visibility, velocity, and variability

- Information enablers—management of quality, timeliness, and depth of information

- Leveraging technologies—agents and RFID

In order to achieve success in managing supply chain network where more than one companies interact with each other, an organization must possess and share knowledge about the different facets of the supply chain by engaging their supply chain partners in interlinked processes that enable rich information sharing, and building information technology infrastructures that allow them to process information obtained from their partners.

2.1.2 Problems within Supply Chain

According to Turban (2008), problems along the supply chain can occur between business units within a single enterprise; they also can occur between (and among) enterprises. A major symptom of ineffective supply chains is poor customer service, high inventory costs, loss of revenues, and extra cost of expediting shipments.

Furthermore Turban added that problems along the supply chain stem mainly from two sources:

1. From uncertainties

2. From the need to coordinate several activities, internal units, and business partners.

Actual demand for a product is influenced by several factors such as competition, prices, weather conditions, technological developments, and customers’ general confidence. These are external, usually uncontrollable, factors (solutions: measuring demand in real time and using a demand-driven production strategy).

Other supply chain uncertainties include delivery times, which depend on many factors, ranging from production machine failures to road conditions and traffic jams that may interfere with shipments. Quality problems in materials and parts may also create production delays, which lead to supply chain problems.

2.2 Knowledge Management

Davenport and Prusak (1998) provide a valuable discussion of knowledge: ‘Knowledge is a fluid mix of framed experience, values, contextual information, and expert insight that provides a framework for evaluating and incorporating new experiences and information. It originates and is applied in the minds of knowers. In organizations, it often becomes embedded not only in documents and repositories but also in organizational routines, processes, practices and norms’.

While according to Probst (2001), knowledge is the whole body of cognitions and skills which individuals use to solve problems. It includes both theories and practical, everyday rules and instructions for action. Knowledge is based on data and information, but unlike these, it is always bound to person.

The European framework for knowledge management (Mekhilef et al., 2003) defines data, information and knowledge as:

- Data. Discrete, objective facts (numbers, symbols, figures) without context and interpretation

- Information. Data which adds value to the understanding of a subject and in context is the basis for knowledge.

- Knowledge. The combination of data and information, to which is added expert opinion, skills and experience, to result in a valuable asset which can be used to aid decision making.

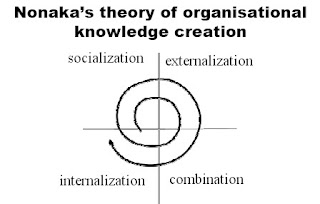

Nonaka and Takeuchi (1995) introduce two definitions of knowledge:

- Explicit knowledge deals with more objective, rational, and technical knowledge (data, policies, procedures, software, documents, etc.). Explicit knowledge can be readily detailed in procedural manuals and databases.

- Tacit Knowledge is usually in the domain of subjective, cognitive, and experiential learning; it is highly personal and difficult to formalize. It refers to experience on how to react to a situation when many different variables are involved and it is often resides in the heads of employees.

Fig. 2: Organizational Knowledge Creation

Furthermore, Nonaka and Takeuchi (1995) identify four different processes in which knowledge is created and transferred. They are:

- Tacit to tacit through a process of socialization; e.g. the marketing manager discusses and learns about latest sales trends with a sales executive.

- Tacit to explicit through a process of externalization; e.g. another sales executive sends an e-mail putting forward their thoughts on what the new pricing structure should be.

- Explicit to tacit through a process of internalization; e.g. the marketing manager reads and understands the reports to develop a new insight and understanding of the situation (knowledge).

- Explicit to explicit through a process of combination; e.g. the marketing manager combines knowledge from reports produced from the database to produce an overview of the current situation.

Here is a traditional dimension to define what knowledge does an organization wants to know (Zachman 2001):

• Things of the business (What) – What are the things of significance to the organization about which it wants to know something? What resources (physical and intellectual) exist?

• Processes (How) – What does the company do? What should it be doing? How does it work?

• Distribution and geography (where) – Where does the company do business? How do people, materials, money, and information travel from place to place?

• The organization (who) – What is the company’s organization? This whole change in orientation towards knowledge management is having profound effects on the organization. What does this mean?

• Events, agents, responses (when) – What role does time play in the company’s operations? What events cause things to happen? Who responds and in what ways?

• Motivation and Business rules (why) – What are the company’s objectives, and how are they translated into business rules?

Kelleher and Levene (2001), introducing knowledge management as: ‘The capabilities by which communities within an organization capture the knowledge that is critical to hem, constantly improve it and make it available in the most effective manner to those people who need it, so that they can exploit it creatively to add value as part of their work’.

Knowledge Management provides processes to capture a part of tactic knowledge through informal methods and pointers and fairly high percentage of explicit knowledge, reducing the loss of organizational knowledge (Nonaka and Takeuchi, 1995).

With this we can define the functions of Knowledge Management System:

• Enable knowledge capture and exchange

• Facilitate the acquisition, documentation, transfer, creation and application of knowledge

• Ensure greater knowledge functionality by make it available to those people who need it.

Heisig and Iske (2003) briefly explained the five core processes the European Framework for Knowledge Management:

1. Identify knowledge: people need to think about what they want to achieve and the knowledge required to make it happen. If knowledge is lacking a knowledge gap needs to be identified.

2. Create knowledge: new knowledge is created by training, learning by doing and problem solving—creating new knowledge for products and services. Innovation is vital to this process

3. Store knowledge: knowledge assets form of the knowledge base of an organization. These assets may be stored in documents or databases or memorized as tacit knowledge

4. Share knowledge: distribution to the right people at the right time. The stock approach is when knowledge is shared via documents and databases; a flow approach is when knowledge is shared person-to-person.

5. Use knowledge: applying what we know, used in the business processes.

2.2.1 IT in Knowledge Management

Many organizations mistakenly assume that KM is about the use of information technology and that technology could replace the skill and judgement of an experienced human worker. Technology does, however, aid in the exchange of information and knowledge within and outside the organization (Davenport and Prusak, 1998).

KM is more a methodology applied to business practices than a technology or product. Nevertheless, IT is crucial to the success of every KM system. IT enables KM by providing the enterprise architecture on which it is built.

2.2.2 Knowledge Management Integration with Supply Chain Management Systems

The supply chain is often considered to be the logistics end of the business. If products do not move through the organization and go out the door, the firm will fail. So it is important to optimize the supply chain and manage it properly.

The keys are collaboration and trust because the model for creating business value is changing. It is generally believed that increased collaboration among supply chain participants leads to lower total cost and enhanced service performance. Companies today participated in extended supply chains, where real operational efficiency and revenue enhancement can only come from greater visibility, integration and synchronization among connected partners. A successful supply chain needs to be customer-focused, flexible, timely, financially accurate and damage-free.

SCM can benefit through integration with KMS because there are many issues and problems in the supply chain that require the company to combine both tacit and explicit knowledge. Accessing such knowledge will directly improve supply chain performance

3.1 Case Study Wal-Mart

Wal-Mart is a very good example of how supply chain was managed very well by using technology and knowledge management. Without a doubt, Wal-Mart is one of the best supply chain operators at the moment. Wal-Mart Stores, Inc. (branded as Wal-Mart) is an American public corporation that runs a chain of large, discount department stores.

Wal-Mart was one of the largest private sector employers in the world, with employee strength of approximately 2.1 million in 2009. It has revenue of 404.16 Billion in 2009. According to analysts, Wal-Mart was able to achieve a leadership in the retail industry because of its efficient supply chain management practices.

The company’s founder, Sam Walton had always focused on improving sales, constantly reducing costs, adopting efficient distribution and logistics management systems and using innovative information technology tools.

Wal-Mart Goals are a focus on satisfying customer needs by:

- Providing customers access to goods when and where they want them

- Low cost structures that enable competitive pricing

3.2 Managing the Supply Chain

3.2.1 Procurement and Distribution

Wal-Mart spent a significant amount of time meeting vendors and understanding their cost structure. By making the process transparent, Wal-Mart could be certain that the manufacturers were doing their best to cut down costs.

Wal-Mart always emphasized the need to reduce its purchasing costs and offer the best price to its customers. The company procured goods directly from manufacturers, bypassing all intermediaries.

Every employee had an access to real-time information regarding the inventory levels of all the products. The hand-held computer enabled the packaging department to get accurate information about the products to be packed. It displayed all information about the storage, packaging and shipping of a particular product thus, saving time on unnecessary paperwork.

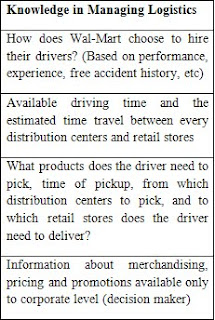

3.2.2 Logistics Management

An important feature of Wal-Mart’s logistics infrastructure was its fast and responsive transportation system. The coordinator scheduled all dispatches depending on the available driving time and the estimated time for travel between the distribution centers and the retail stores. The driver was usually expected to take a loaded truck trailer from the distribution center to the retail store and return back with an empty trailer.

To make the distribution process more efficient, Wal-Mart also made use of logistics technique known as ‘cross-docking’. In this system, the finished goods were directly picked up from the manufacturing plant of a supplier, sorted out and then directly supplied to the customers. The system reduced the handling and storage of finished goods, virtually eliminating the role of distribution centers and store.

To gain maximum out of cross-docking, Wal-Mart had to make fundamental changes in its approach to managerial control. Traditionally, decisions about merchandising, pricing and promotions had been highly centralized and were generally taken at the corporate level. The system shifted the focus from “supply chain” to the “demand chain”, which meant that instead of retailer ‘pushing’ products into the system; customers could ‘pull’ products, when and where they needed.

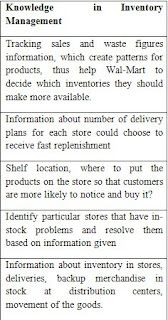

3.2.3 Inventory Management

Wal-Mart had developed an ability to cater to the individual needs of its stores. Stores could choose from a number of delivery plans. For instance, there was an accelerated delivery system by which stores located within a certain distance of a geographical center could receive replenishment within a day.

Wal-Mart invested heavily in IT and communications systems to effectively track sales and merchandise inventories in stores across the country.

Wal-Mart was able to reduce unproductive inventory by allowing stores to manage their own stocks, reducing pack sizes across many products categories, and timely price markdowns.

Wal-Mart made full use of its IT capabilities to make more inventories available in the case of items that customers wanted most, while reducing the overall inventory levels.

Wal-Mart also networked its suppliers through computers. Wal-Mart entered into collaboration with suppliers for maintaining the inventory in its stores and built an automated re-ordering system, which linked all computers between suppliers and its stores and other distribution centers.

3.3 Knowledge Management System in Wal-Mart (Retail Link System)

The feat or restricting inventory growth, while simultaneously opening new stores and staying in stock hack a lot to do with distribution centers and a private truck fleet, but equally important is the company’s Knowledge Management System known as Retail Link.

In 1991, Wal-Mart had invested approximately $4 billion to build a Retail Link system. More than 10,000 Wal-Mart retail suppliers used the retail link system to monitor sales of their goods at stores and replenish inventories. The details of daily transactions, which approximately amounted to more than 10 million per day, were processed through this integrated system.

In existence, more than a decade Wal-Mart has made consistent upgrades to the system that provides suppliers with up to two years of sales history to analyze their business.

Retail Link is said to be in a class of its own because of the sheer amount of information available at the touch of a button. Retail Link manager Calum Macrae (2005) said “anyone with access to the system can get complete information about any one product at any given time. And its last—the average retrieval time on a query is about one minute, pretty good considering the system gets 24,000 queries from the UK alone in an average week.

With Retail Link Wal-Mart has been able to identify particular stores that have in-stock problems and then take action to resolve them. When inventories fall to certain levels or when other criterion is met, the vendor can have new stock delivered to anywhere Wal-Mart needs the merchandise.

3.4 Defining Knowledge in Wal-Mart

With Zachman (2001) framework we can define what knowledge does Wal-Mart wants to know:

• Things of the business (What) – Wal-Mart needs to know how to reduce their cost while increasing their services at the same time. Thus they need to know the cost structure of every product from the suppliers. Other things they need to know are the availability of the products and supplier performance.

• Processes (How) – Wal-Mart is collecting various products from many suppliers. They need to know how to move the goods efficiently. Right from picking up the goods from supplier plants, distribute it to distribution channel or straight to the retail store or customers. Wal-Mart also needs to establish good and sustainable relationships with its suppliers.

• Distribution and geography (where) – Wal-Mart is doing business on a global scale. So Wal-Mart has to cope with different and changing regulatory demands across the regions where it operates; it has to deal with logistical issues on an international scale.

• The organization (who) – Wal-Mart is an industry retail store, thus they would need to know about market preferences for every products from their suppliers. Wal-Mart has to manage each retail store supply chain. With the use of Retail-Link system, their suppliers help them by managing their own products. Information and knowledge need to flow without problems across the networks in order to minimize error.

• Events, agents, responses (when) –Responses is very crucial in the organization. It plays an important role in lead time, inventory turnover and better services.

• Motivation and Business rules (why) – Wal-Mart objective is to provide every products that is cheaper than elsewhere. It means they need to have a transparency between their suppliers, without sharing their information and knowledge it will be very hard to achieve their mission. While they share information and knowledge with their suppliers, Wal-Mart only shared the information and knowledge related to each of supplier products.

There are some keys knowledge the writer can identified in Wal-Mart based on case study and references collected:

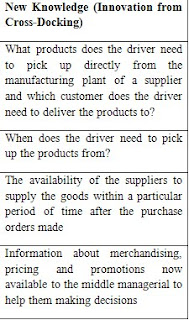

Table 1. Knowledge in Managing Procurement and Distribution

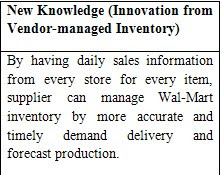

Table 2. Knowledge in Inventory Management

Table 3. Knowledge in Managing Logistic

Table 4. Knowledge in Cross Docking System

Table 5. Knowledge in Vendor Managed Inventory System

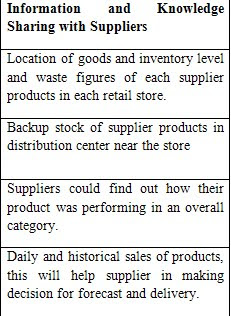

Table 6. Knowledge Sharing with Suppliers

3.5 Issues in Retail Link System

However good the knowledge management system was, if the information and knowledge did not get to the right person or the users are not willing to use it because they do not feel comfortable, then the knowledge will be useless and won’t bring any goods to organization because there is no action taken.

Wal-Mart faced two issues when they first introduced Retail Link system:

1. The knowledge did not get to the right person.

2. Ease of use of the system.

Tom Goughlin, president and CEO of the Wal-Mart Stores Division, said “Early on, far too many companies designated somebody at a low rank to be responsible for the coordination of retail link and we both missed far too many opportunities." According to Coughlin, it is "extremely important" to have people of a high enough rank within a supplier's organization devoted to Retail Link so as to have an impact.

In a bid to get more senior supplier executives to use Retail Link, for example, Wal-Mart developed a new analysis tool called Business-at-a Glance. It is designed to help executives who may be less technologically savvy use the information in the retailer’s database to make quick, fact based decisions

In addition to promoting usage of Retail Link at a senior level within supplier organizations, Wal-Mart also solicits input from suppliers on how to improve the system. Wal-Mart sponsored Retail Link User Groups to meet regularly around the country where participating suppliers can share tips and strategies for increasing the effectiveness of the system. Wal-Mart also has a Retail Link steering committee comprised of members of the supplier community that meets quarterly and is able to share suggestions on how to improve the functionality of the system.

3.6 Key Success of Knowledge Management in Wal-Mart

The successful of KM initiative on Wal-Mart supply chain depends on many factors and can be identified as:

1. Supportive leadership—high-level support removes the resistance to information and knowledge sharing across the networks. According to Cliff & Rhine (2002), unless the top tiers of the leadership hierarchy recognize the importance of knowledge exchange in culture, there is little hope that grass-roots efforts will transform the entire organization. Clearly Wal-Mart CEO visibility in implementing and promoting the use of Retail Link is one of the key successes. The management spent a lot of effort in promoting the use of the system to its internals or suppliers.

2. Clear intentions of what are important—In their book, Working Knowledge, Thomas Davenport and Laurence Prusak emphasize that “intentions are important: a firm needs to know what it wants to have a good chance of getting it”. Wal-Mart had a clear view and description of its goals. They know what kinds of knowledge its network is meant to discover and how that knowledge will advance its overall strategy. They provide the right information and knowledge for their suppliers, so the suppliers can do their process more efficiently.

3. Knowledge sharing practices across the networks— Knowledge sharing is about dynamic information exchange and communication. Its technical challenges have to do with interaction, the retrieval of stored information, and the constant gathering of new information. Wal-Mart and its’ suppliers key players, who may range from specialized teams to cross-discipline experts to entire departments, were enabled to interact through the network with one another and with information resources. As part of the process, these knowledge sharing communities were able to produce new collections of information, based on their interaction, conversation, and the content they create and gather, that can be categorized, searched and retrieved.

4. Technology-savvy throughout the organization—While Wal-Mart partners / suppliers may be less technologically savvy to take full advantage of the systems, Wal-Mart developed new tools that are much simpler and easier to use.

5. Information / knowledge filtering to its suppliers, Wal-Mart only provides suppliers with data on their own brands and overall categories, not competitors’ brands.

6. New management structure of supply chain management. Wal-Mart adapting their organizational structure to the business and requirement change.

7. New leveraging technology, Wal-Mart keeps using innovative technology tools such as satellite, Barcode, RFID, etc. They keep upgrading their system and technology.

3.7 Conclusion

The benefits of an efficient Knowledge Management in supply chain management included reduction in lead time, faster inventory turnover, accurate forecasting of inventory levels, increased warehouse space, reduction in safety stock and better working capital utilization. It also helped reduce the dependency on the distribution center management personnel resulting in minimization of training costs and errors.

To support the inter-organizational sharing of resources and competencies in a network structure, communication and coordination need to be maintained. Wal-Mart has successfully redesigned their internal structure and their external relationships, creating knowledge networks to facilitate improved communication of data information and knowledge, while improving coordination, decision making and planning.

The set of processes Wal-Mart has established for efficient retailing are information driven. Processes are knowledge that enables a business enterprise to execute its business. The ultimate goal of a knowledge network is to make the jobs of its users simpler, easier, and more effective. Knowledge networks allow their participants to create, share, and use strategic knowledge to improve operational and strategic efficiency and effectiveness.

Retail Link system helped Wal-Mart and their suppliers accelerate their business. By using Retail Link Wal-Mart and its suppliers get a better handle on the runaway growth of useful information by somehow taking control of the sources of that information and not losing information that had been located and captured. The other was to manipulate information to answer vital business questions in an increasingly complex and fast-changing world. The better the supplier do their process, the more Wal-Mart can sell, and the more quickly it can sell, the more money Wal-Mart will make.

References

Turban (2008) Information Technology for Management, Wiley International Student Version.

Dave Chaffey & Steve Wood (2005) Business Information Management-Improving performance using Information Systems, Prentice Hall

Davenport & Prusak (1998) Working Knowledge, Harvard Business School Press

Nonaka & Takeuchi (1995) The knowledge creating company, Oxford Univ. Press.

Probst, G., Raub, S., Romhardt, K. (2001), Managing Knowledge – Building Blocks for Success, Wiley: Chichester.

Kelleher, D. & Levene, S. (2001) Knowledge management - a guide to good practice. London: British Standards Institution.

Heisig, P. and Iske, P. (2003) European knowledge management framework. In European Guide to Good Practice in Knowledge Management

Mekhilef, M et al (2003) European Guide to Good Practice in Knowledge Management.

Cliff Figallo & Nancy Rhine (2002) Building the Knowledge Management Network.

http://www.tdan.com/view-articles/4832 - Knowledge Management (David C. Hay)

http://mohanchandran.files.wordpress.com/2008/01/wal-mart.pdf Case Study | Wal-Mart Supply Chain Management Practices

http://findarticles.com/p/articles/mi_m0FNP/is_11_41/ai_87146180/?tag=content;col1 Competitive advantage lies in systems efficiencies - Supply Chain - Wal-Mart

http://en.wikipedia.org/wiki/Zachman_Framework

I like your management thoughts. Its a good thing. But now the Penny Stocks Investment is the best way to earn money. Last week i have invested $1200 in Hototc.com and within just 6days i will get $3680. Its a great success for me. To know how i will get this log on to the website.

ReplyDeletethanks for info..

ReplyDeletenice blog

I learned a lot about Supply Chain and Logistics Management from this post. Very detailed and informative with references too! Thanks

ReplyDeleteWith 30 years of rich experience in managing warehouse operations and strength of 400 employees, Jayem Logistics proves to be the largest warehousing and inventory management in India.

ReplyDeleteTop logistics service provider in India

Does your blog have a contact page? I’m having problems locating it but, I’d like to shoot you an email. I’ve got some recommendations for your blog you might be interested in hearing.Surya Informatics

ReplyDelete